The four-page general industry standard (29 CFR 1910.147), published in September 1989, was designed to prevent the accidental start-up of machines or other equipment during maintenance and servicing. Under the rule, hazardous energy sources must be "isolated and rendered inoperative" before work can begin. Hazardous energy sources include electrical, mechanical, hydraulic, pneumatic, chemical, thermal or just plain gravity.

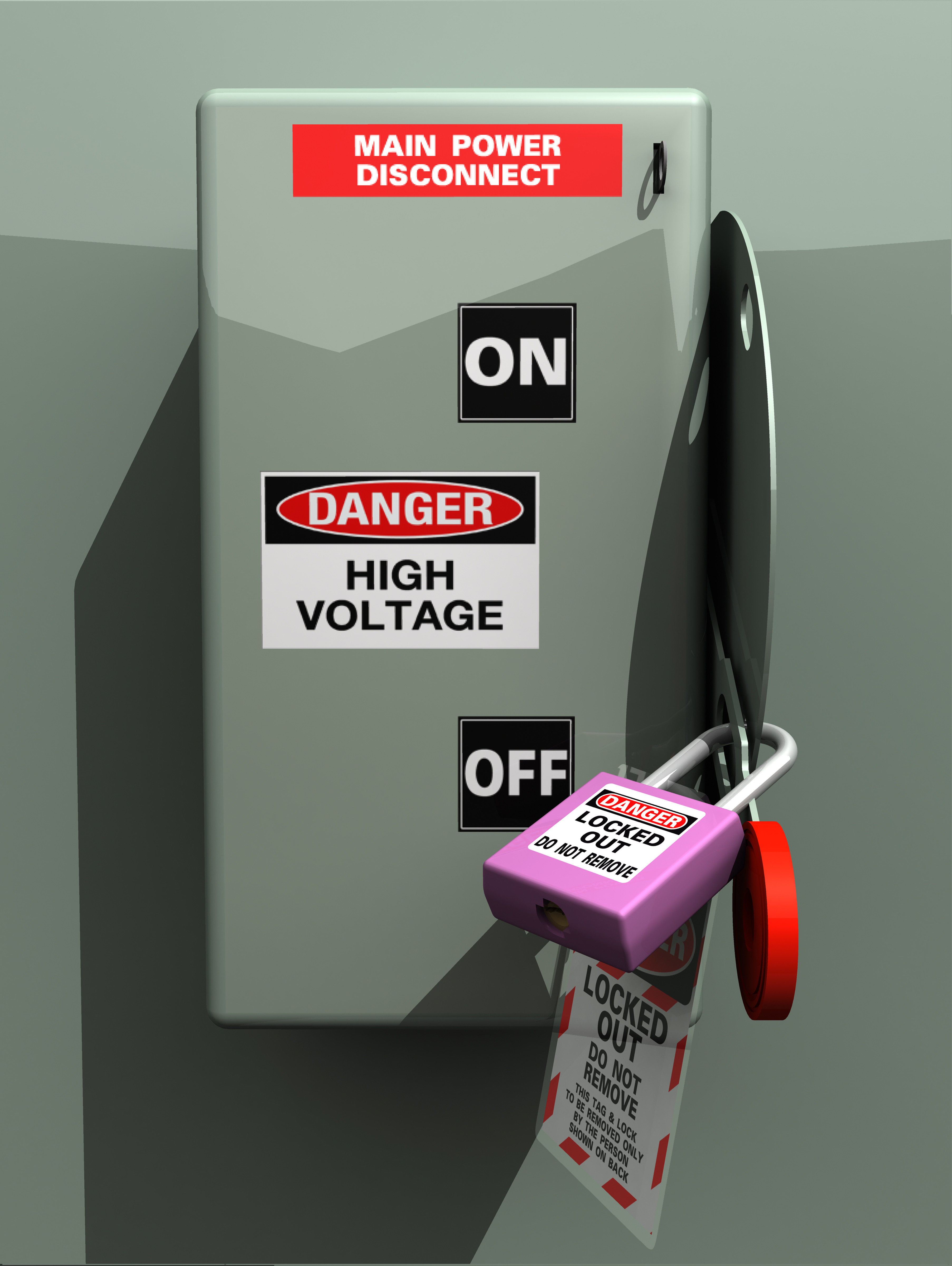

Energy isolating devices, such as a disconnect switch or manually operated electrical circuit breaker, must be locked in place (lockout) or, in certain circumstances, labeled with a tag (tag-out) warning against start-up until servicing is finished. Each employee who will be working on the equipment applies a lock or tag to all energy isolating devices. Stored energy, such as air pressure, must then be released or "otherwise rendered safe"; and energy isolation must be verified by an attempted start-up before work begins. The machine cannot be restarted after servicing until each person has removed his/her lock or tag. According to OSHA, a lockout/tag-out program must include three basic elements.

1. Written procedures for controlling hazardous energy releases from each piece of equipment. They should describe preparation for shutdown, actual shutdown, equipment isolation, steps for applying and removing lockout/tag-out devices, requirements for testing that hazardous energy has indeed been isolated, and notification of employees.

2. Training for: "authorized" employees who do the maintenance and servicing work and must know how to safely isolate energy sources before beginning work; "affected" employees who might be working in the vicinity of a locked-out machine and must understand the hazards of attempting a start-up; and "other"employees who might be walking through part of a plant where a machine is locked out.

3. Periodic audits, at least once a year, of the overall program. This inspection must be done by an authorized employee who is not actively involved in the energy control procedures being inspected.

This 4-hour course trains employees on the proper LOTO procedures. Some of the topics which are covered include: awareness, attitude and actions to take; when, where and why to use LOTO; proper locking/tagging procedures and communication.